Automobile oil and gas hoses are mainly used in automobile engine fuel systems and liquefied petroleum gas systems to transport fuel or liquefied petroleum gas to the engine or other components in the fuel system. These hoses are usually subjected to high pressure and high temperature environments, so they need to be resistant to high pressure, corrosion, and wear.

In automobile fuel systems, hoses connect components such as fuel pumps, fuel tanks, fuel filters, and fuel injectors to transport fuel from the fuel tank to the engine combustion chamber. In the liquefied petroleum gas system, the hose connects the gas bottle and the engine's gas supply system to transport the liquefied petroleum gas to the engine to supply gas.

Therefore, automobile oil and gas hoses play a vital role in the normal operation of the car and require regular inspection and maintenance to ensure that they deliver fuel or gas safely and reliably.

Things to note when using automotive oil and gas hoses include:

1. Regular inspection: Regularly check the appearance of the hose for cracks, aging, deformation or wear to ensure that the hose is intact.

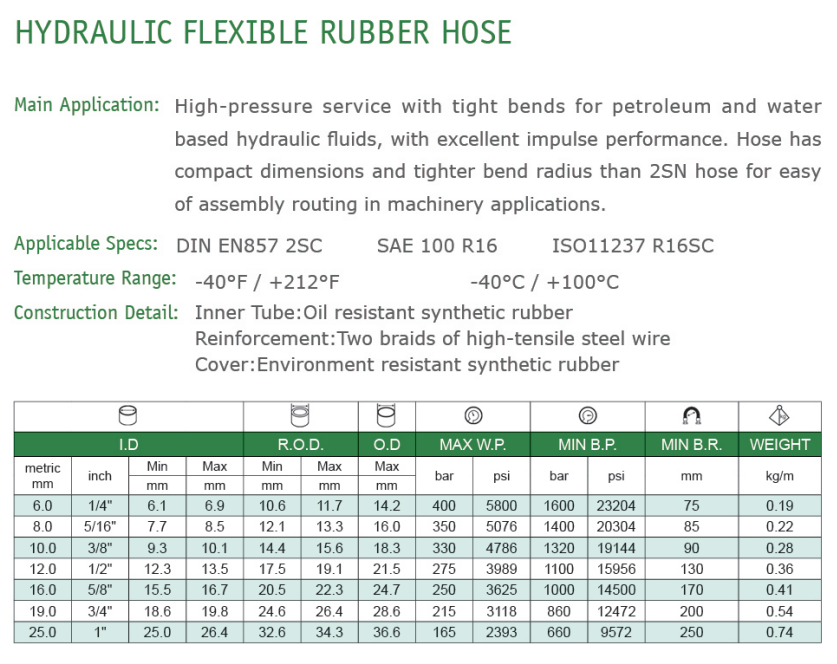

2. Pressure level: Use high-pressure hoses that meet the requirements of automobile fuel systems or liquefied petroleum gas systems to ensure that the hoses can withstand the pressure within the system.

3. Corrosion resistance: Select corrosion-resistant hose materials according to the actual use environment to prevent damage to the hose in corrosive environments.

4. Installation method: Install the hose correctly to avoid twisting or squeezing the hose and ensure that the hose is firmly connected.

5. Temperature range: Choose a hose that meets the requirements of the operating temperature range to avoid problems with the hose in high or low temperature environments.

6. Replacement cycle: According to the usage of the hose and the replacement cycle recommended by the manufacturer, aging or severely worn hoses should be replaced regularly.

7. Usage environment: Avoid the hose coming into contact with sharp objects or being exposed to harsh environments such as high temperature and chemical corrosion.

Following these usage precautions can ensure the safe and reliable operation of automobile oil and gas hoses and reduce safety hazards caused by hose problems.