Our waterstops are made from a premium blend of natural rubber and various synthetic rubbers, ensuring exceptional durability and performance. Each product is carefully formulated with selected additives and fillers, then formed through a precise plasticizing, mixing and pressing process. Attention to detail ensures our waterstops provide superior sealing capabilities, effectively preventing water ingress into critical structures.

We understand the challenges of water management and design strip waterstops to stand the test of time, even in the most demanding environments.

Our high-quality strip waterstops are more than just products. They are solutions designed to increase the longevity and integrity of your project. Whether you are working on a large infrastructure project or a small construction job, our waterstops are versatile enough to meet your specific needs.

1. Durability: Made from a blend of natural rubber and various synthetic rubbers, these waterstops are engineered to withstand harsh environmental conditions, ensuring long-lasting performance.

2.Flexibility:The unique composition provides excellent flexibility, allowing the waterstop to adapt to the movement of the structure without affecting its sealing ability.

3.Easy to Install: The molded design simplifies the installation process, making it easier for construction teams to integrate it into their projects.

4.Chemical Resistance: Our Ribbon Waterstop are resistant to a wide range of chemicals, making them suitable for use in a variety of environments, including wastewater treatment facilities and industrial applications.

5.Cost Effectiveness: By preventing water damage, these waterstops can save significant repair and maintenance costs over the life of the structure.

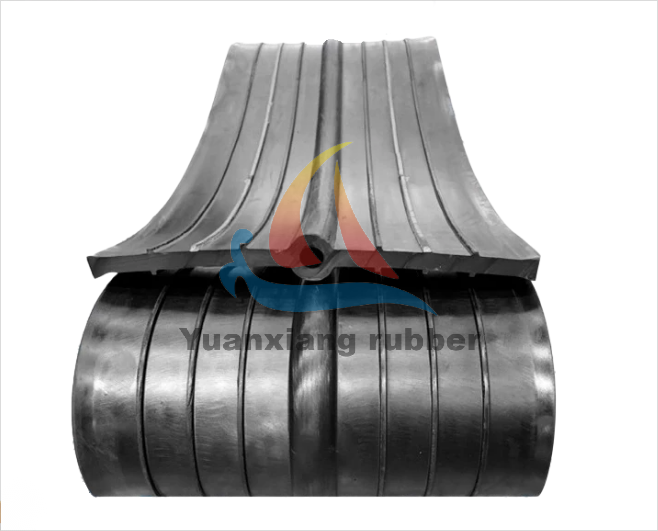

Buried rubber waterstop

The mid-buried rubber waterstop is a waterstop product mainly used in concrete deformation joints, expansion joints, etc. It has the ability to adapt to the expansion and deformation of concrete with the elasticity and structural form of rubber materials. This product uses the high elasticity and compression deformation of rubber to produce elastic deformation under various loads, so as to play a fastening and sealing role, effectively prevent water leakage and water seepage of building components, and play a role of shock absorption and buffering, which can ensure engineering construction lifespan of the thing.

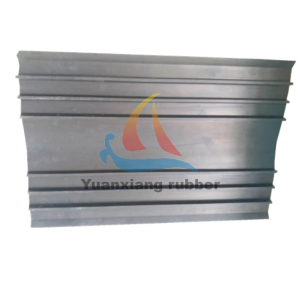

Back-mounted rubber waterstop

The back-adhesive rubber waterstop uses the high elasticity of rubber to produce elastic deformation under various loads, so as to achieve a strong seal, effectively prevent water leakage and seepage of the building structure, and play a role in shock absorption and buffering. In many engineering and architectural designs, there are certain expansion and contraction requirements between civil engineering and water and soil structures, and there are problems such as waterproof and shockproof. Therefore, the use and installation of rubber waterstops is an effective means to solve the above problems. This product is mainly used for foundation projects, underground facilities, tunnel culverts, aqueducts, retaining dams, etc. that are integrated with concrete structures in construction joints and deformation joints when concrete is poured in place, to ensure the service life of engineering construction.

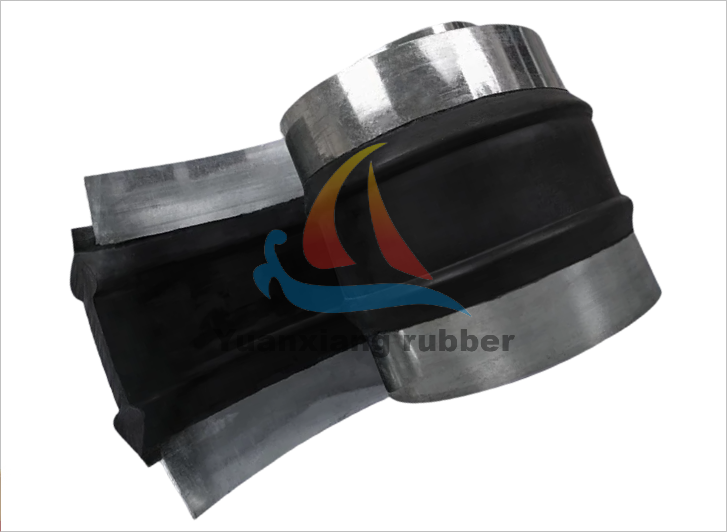

Steel edge waterstop

The steel-edged rubber waterstop is that the section of the rubber waterstop adopts a non-uniform thickness structure, which is divided into a strong area and a waterproof area, so that the force on each part is even and reasonable. Installing holes are added on the steel plate of the waterstop to connect with the steel bars, so that the fixing is firm and not easy to displace, so that the force on each part is even and reasonable. The long wall of the telescopic hole of the steel edge waterstop is flat. During the construction of the waterstop, the clamping contact surface of the formwork is large, and it is not easy to dislodge;

water-swellable waterstop

The water-swellable waterstop will gradually expand after encountering water, and finally

Slowly block the capillary pores that exist all over the place, making the contact with the concrete interface more closely, thereby generating greater water resistance pressure and forming an impermeable plastic colloid. This product has the characteristics of high expansion ratio and strong mobile supplementary performance. After being placed in the construction joint pouring joint, it has a strong balance self-healing function, and can automatically seal the new tiny gaps caused by settlement. For the completed project, if the gap leaks water, it can be re-plugged with a water stop strip , low construction cost and simple construction process, excellent corrosion resistance.

1. Durability: High-quality strip waterstops are made from a blend of natural and synthetic rubber, ensuring they can withstand harsh environmental conditions. This durability means a longer lifespan, reducing the need for frequent replacement.

2. EFFECTIVE SEAL: These waterstops are designed to create a watertight seal in building joints to prevent water intrusion. This is especially important for structures such as dams, basements, and water treatment facilities.

3. VERSATILITY: Rubber waterstops can be molded into a variety of shapes and sizes, making them suitable for different applications. Their adaptability allows seamless integration into a variety of construction projects.

4. Cost Effectiveness: While the initial investment may be higher, reduced maintenance and repair costs can save money in the long run, making high-quality strip waterstops a smart choice.

1. Initial Cost: The upfront cost of high-quality ribbon waterstops can be a roadblock for some projects, especially smaller projects on a tight budget.

2. Installation Complexity: Proper installation is critical for optimal performance. If installed incorrectly, the effectiveness of the waterstop can be compromised, leading to potential water damage.

3. Material Sensitivity: Some synthetic rubbers, while durable, may be sensitive to extreme temperatures and chemicals, which may limit their use in certain environments.

1. Sample service

We can develop sample according to information and design from customer.Samples are provided free of charge.

2. Custom service

The experience of cooperating with many partners enable us to provide excellent OEM and ODM services.

3. Customer service

We are dedicated to providing the best service to global customers with 100% responsibility and patience.

Q1: How to install strip waterstop?

A: Installation typically involves placing waterstops in the concrete joints prior to pouring. Make sure it is properly aligned and secured to prevent movement.

Q2: Can strip waterstops be used on all types of construction?

A: Yes, they are versatile and can be used in a variety of applications, including basements, tunnels and water treatment facilities.

Q3: What is the service life of strip waterstops?

A: With proper installation and maintenance, high-quality strip waterstops can last for decades, providing reliable protection from water penetration.