Main feature

1. High Pressure Resistance: One of the outstanding features of high-performance chemical hose is its ability to handle high pressure. This is particularly important for industries involved in transporting vehicle engine fuel or liquefied petroleum gas. The rugged construction of these hoses ensures they can withstand intense pressure without compromising safety or performance.

2. Chemical Compatibility: These hoses are engineered to withstand a wide range of chemicals and are suitable for a variety of industrial applications. Whether acids, solvents or fuels, high-performance chemical hoses provide the necessary durability and reliability.

3. Flexibility and Maneuverability: Although these hoses are strong, they are designed to be flexible and can be easily installed and moved in tight spaces. This feature is critical for industries that require frequent adjustments and repositioning of equipment.

4. Temperature Resistant: High-performance chemical hoses can operate effectively over a wide temperature range, ensuring they maintain integrity and performance even under extreme conditions.

Precautions

Things to note when using automotive oil and gas hoses include:

1. Regular inspection: Regularly check the appearance of the hose for cracks, aging, deformation or wear to ensure that the hose is intact.

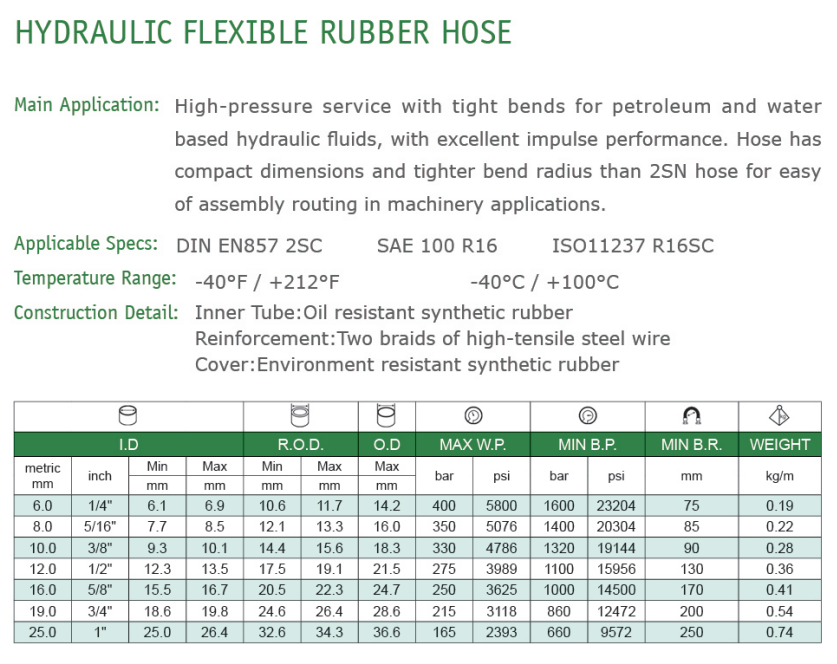

2. Pressure level: Use high-pressure hoses that meet the requirements of automobile fuel systems or liquefied petroleum gas systems to ensure that the hoses can withstand the pressure within the system.

3. Corrosion resistance: Select corrosion-resistant hose materials according to the actual use environment to prevent damage to the hose in corrosive environments.

4. Installation method: Install the hose correctly to avoid twisting or squeezing the hose and ensure that the hose is firmly connected.

5. Temperature range: Choose a hose that meets the requirements of the operating temperature range to avoid problems with the hose in high or low temperature environments.

6. Replacement cycle: According to the usage of the hose and the replacement cycle recommended by the manufacturer, aging or severely worn hoses should be replaced regularly.

7. Usage environment: Avoid the hose coming into contact with sharp objects or being exposed to harsh environments such as high temperature and chemical corrosion.

Following these usage precautions can ensure the safe and reliable operation of automobile oil and gas hoses and reduce safety hazards caused by hose problems.

Product Advantage

1. High Pressure Resistance: One of the outstanding features of high-performance chemical hoses is their ability to withstand high pressure. This is vital for industries that need to transport automotive engine fuel or LPG, ensuring safety and reliability.

2. Durability: These hoses are designed to withstand harsh conditions, including extreme temperatures and corrosive chemicals. This durability means a longer service life, reducing the need for frequent replacement and maintenance.

3. VERSATILITY: High performance chemical hose can be used in a variety of applications from automotive to industrial environments. Their adaptability makes them a valuable asset to companies looking to streamline operations.

4. Enhanced Safety: These hoses feature premium construction and materials that minimize the risk of leaks and spills and avoid hazardous situations. This safety feature is especially important for industries that handle volatile materials.

Product shortcoming

1. Cost: The initial investment in high-performance chemical hose may be higher than standard hose. While they offer long-term savings through durability, the upfront cost can be a barrier for some businesses.

2. Specialized Handling: Due to their advanced materials and construction, these hoses may require specialized handling and installation techniques, which may require additional training for employees.

3. LIMITED AVAILABILITY: Depending on specific requirements, high performance chemical hose may not be as readily available as standard options, which may result in procurement delays.

FAQ

1. What is a high performance chemical hose?

High performance chemical hose is designed to transport a wide range of chemicals safely and efficiently. Engineered to withstand high pressures and resist chemical attack, these hoses are ideal for industrial applications where durability and reliability are critical.

2. What makes our hoses stand out?

Our high-pressure automotive fuel and gas hoses are a prime example of our commitment to quality. These hoses are typically used to transport automotive engine fuel or liquefied petroleum gas. They are designed with features such as high voltage resistance, ensuring they can meet the requirements of rigorous industrial environments.

3. How to choose the right hose?

When selecting high-performance chemical hose, you should consider the following factors:

- Chemical Compatibility: Make sure the hose material is compatible with the chemicals being transported.

- Pressure Rating: Select a hose that can withstand the maximum pressure of the application.

- Temperature Range: Verify that the hose can operate effectively within the temperature limits of your environment.