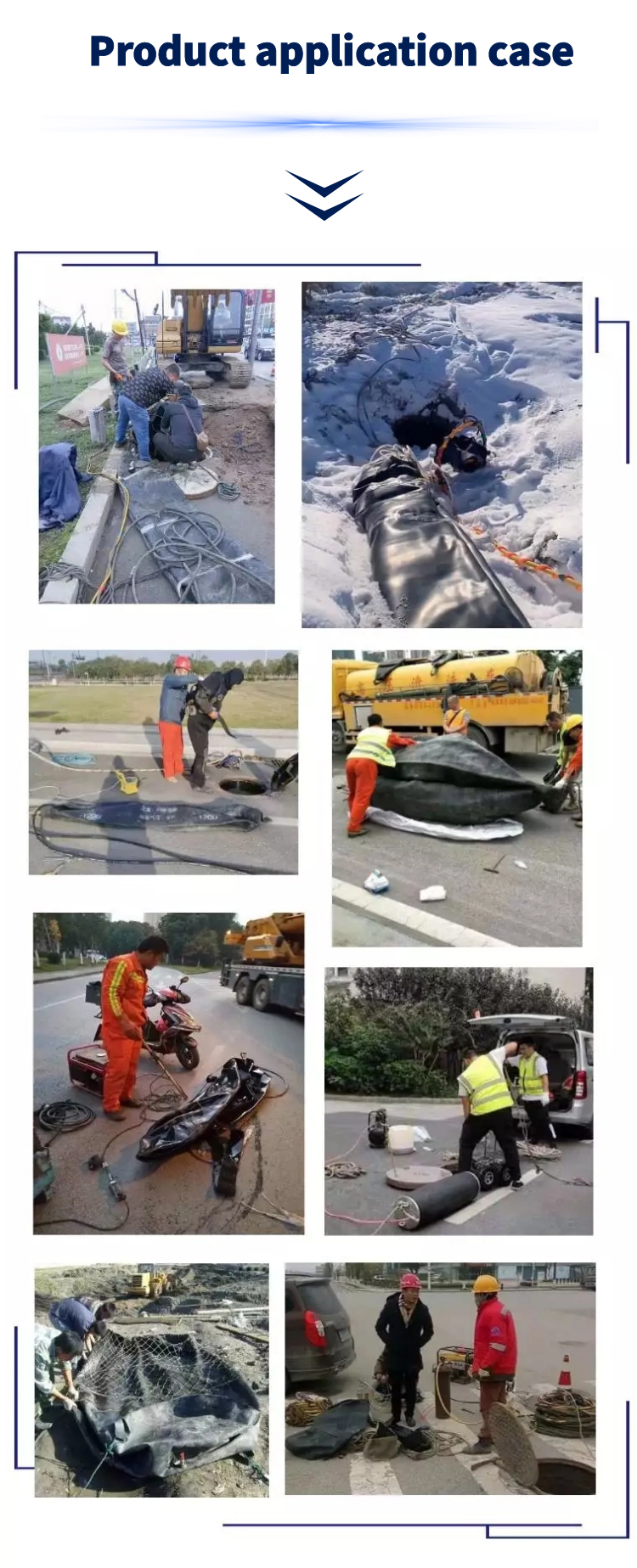

Gas pipeline blocking balls are usually used for gas pipeline maintenance and emergency blocking situations. Their applications include but are not limited to the following aspects:

1. Pipeline maintenance: When performing pipeline repairs, replacing valves or other pipeline equipment, the blocking ball can temporarily seal the pipeline to ensure the safety of the maintenance work.

2. Pipeline testing: When performing pressure testing or leak detection of pipelines, the blocking ball can be used to seal one end of the pipeline for testing to ensure the integrity and safety of the pipeline system.

3. Emergency blocking: When a pipeline leak or other emergency occurs, the blocking ball can be quickly placed at the leak point to block the pipeline, reduce the risk of leakage, and ensure the safety of personnel and equipment.

In general, the gas pipeline blocking ball is an important pipeline blocking equipment that can play a key role in pipeline maintenance, testing and emergency situations to ensure the safe operation of the gas pipeline system.

usage method

1. Select isolation balls of corresponding specifications according to the pipeline and diameter (do not replace them)

2. Before use, check the production and other defects of the isolation ball. Use a pressure reducing valve to fill the nitrogen cylinder with nitrogen gas through the isolation ball tail pipe into the ball. After filling to the pipe diameter size, tie the tail pipe tightly and store for more than 2 hours. After checking for leaks, exhaust the gas for backup.

3. According to your construction situation, open a hole in the pipeline at a certain distance (more than 6 meters) from the pipeline construction site (preferably to accommodate an isolation ball), remove the burrs on the edge of the hole, check that there are no foreign objects or sharp corners inside the pipe, roll the isolation ball into a cylindrical shape and place it into the isolation end of the pipe (construction direction) from the hole, leaving the tail pipe outside. Fill the ball with nitrogen gas through the tail pipe (inflation pressure should not exceed 0.04MPa) gradually to make the isolation ball stick tightly to the pipe wall, and then tie the tail pipe (without air leakage). Check if the residual gas is isolated before construction can proceed.

After the construction is completed, exhaust the gas inside the isolation ball, remove it from the hole, and block the opening.

Product usage precautions

1. The isolation ball is a non model thin-walled rubber product. Cannot withstand pressure, only used for isolating residual gas in the pipeline.

2. For your safety, the gas source must be turned off inside the pipeline using the isolation ball, and pressure operation is not allowed.

3. For the safety and reliability of construction, the isolation ball should not be reused.