Hydraulic hoses are widely used in many industrial and mechanical applications, including but not limited to the following aspects:

1. Construction machinery: hydraulic systems in construction machinery such as hydraulic excavators, loaders, bulldozers, and cranes. Hydraulic hoses are used to transport hydraulic oil to achieve action control of various hydraulic actuators.

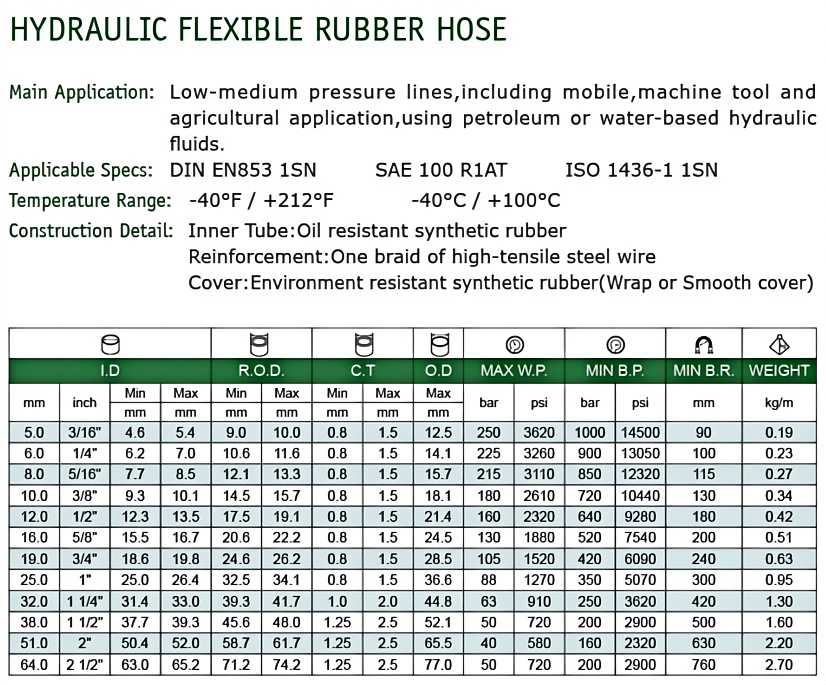

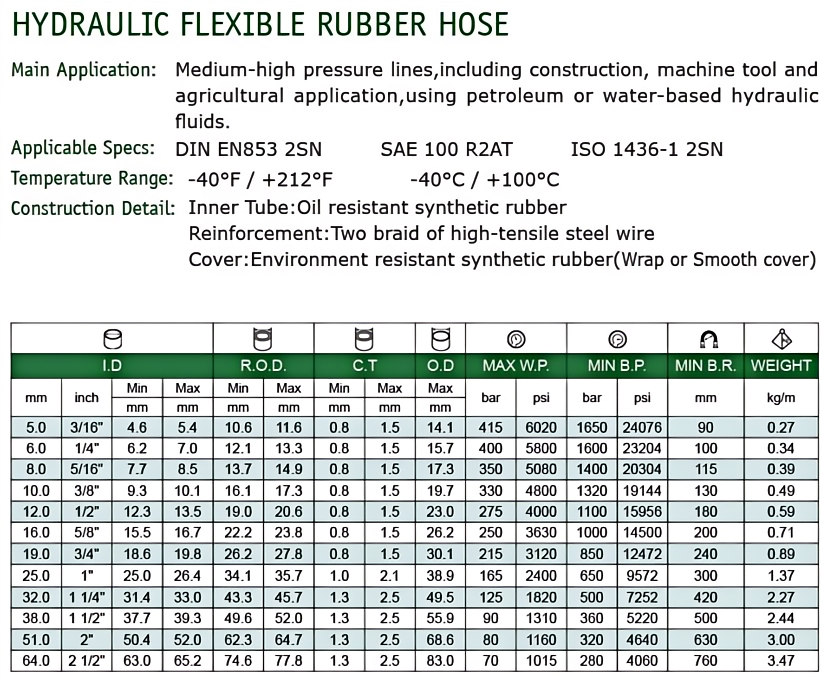

2. Agricultural machinery: Hydraulic systems in agricultural machinery such as tractors, harvesters, and seed drills. Hydraulic hoses are used to realize the hydraulic transmission and control functions of agricultural machinery.

3. Automobile manufacturing: Hydraulic systems such as automobile braking systems, suspension systems, and steering systems. Hydraulic hoses are used to transport brake hydraulic oil, suspension adjustment hydraulic oil, etc. to realize the hydraulic control function of the car.

4. Aerospace: Hydraulic systems in aerospace equipment such as aircraft and spacecraft. Hydraulic hoses are used to transport hydraulic oil to achieve functions such as flight control and landing gear operation.

5. Industrial equipment: hydraulic systems in various hydraulic machinery, hydraulic tooling and other industrial equipment. Hydraulic hoses are used to transport hydraulic oil and realize hydraulic action control of various industrial equipment.

In general, hydraulic hoses have important applications in various machinery and equipment that require hydraulic transmission, hydraulic control and hydraulic actions, and are a key component to realize the functions of the hydraulic system.

Precautions for using hydraulic hoses include:

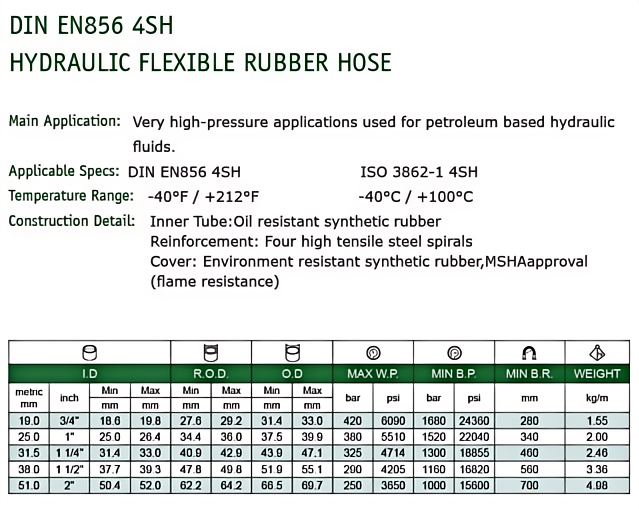

1. Select the appropriate specifications and models: According to the working pressure, flow rate, working temperature and other parameters of the hydraulic system, select the hydraulic hose specifications and models that meet the requirements.

2. Avoid twisting and squeezing when installing: When installing hydraulic hoses, avoid twisting and squeezing to ensure that the hose is firmly connected and will not leak or fall off.

3. Avoid excessive bending: Avoid excessive bending of hydraulic hoses to avoid affecting the flow of hydraulic oil and increasing hose wear.

4. Regular inspection and maintenance: Regularly check the appearance and connection parts of the hydraulic hose to ensure there are no cracks, aging or wear, and replace damaged hoses in a timely manner.

5. Prevent external damage: Avoid damage to the hydraulic hose from sharp objects to ensure the integrity of the hose.

6. Reasonable use: When using the hydraulic system, avoid sudden pressure shocks and overload operations to avoid damage to the hydraulic hoses.

7. Cleaning and maintenance: Keep the hydraulic hose clean to prevent oil and debris from entering the hose and affecting the normal operation of the system.

Following these usage precautions can ensure the safe and reliable operation of the hydraulic hose, extend its service life, and ensure the normal operation of the hydraulic system.